Syngas (a gaseous mixture of CO, H2 and CO2) can be produced by gasification of organic waste materials or biomass, and its valorisation is foreseen as an important process in circular bioeconomy. Carbon monoxide is also produced as a waste gas in many industrial sectors (e.g. chemical, energy, steel). Often, the purity level of bio-based syngas and waste gases is low and/or the syngas composition is not sufficient for an economic chemical application (e.g. Fischer-Tropsch). Microbes have the capability to transform impure syngas to a broad spectrum of products. Syngas fermentation to ethanol has reached demo-scale, but fermentation to chemical building blocks is underexplored. Currently, there are three main bottlenecks in syngas bioconversion: 1) low CO conversion rates to CO, 2) limited product spectra, 3) reduced mass transfer rates of syngas.

This programme brings together a multidisciplinary team of microbiologists and (bio)process engineers to tackle these major gaps by:

1) Discovering novel microbes with high CO-conversion rates and resistance

2) Designing synthetic consortia or engineered microbes for the production of low-solubility molecules or volatiles

3) Evaluating, developing, and testing novel intensified high-cell density bioreactors with enhanced gas-liquid mass transfer and smart product recovery strategies.

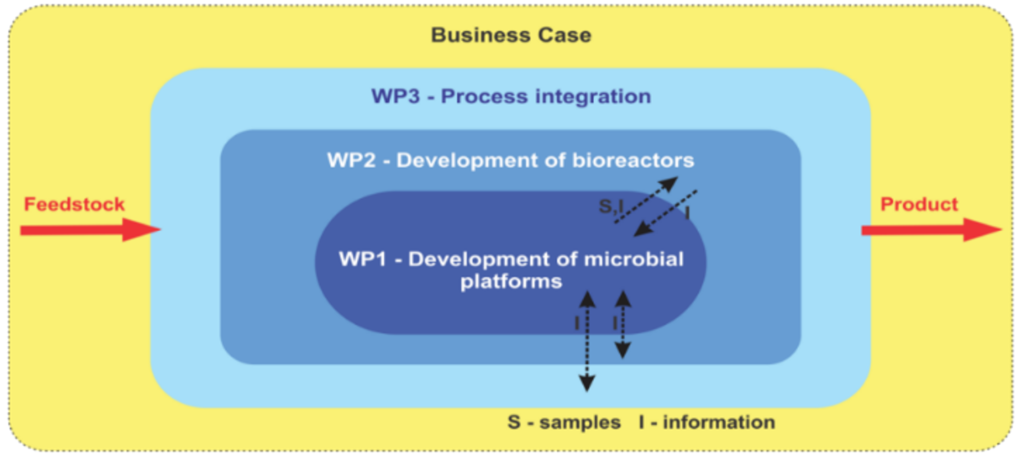

MicroSynC deals with obtaining (1) microorganisms, (2) bioreactors, and (3) overall processes to convert defined syngas feedstocks into desired, recovered products considering overall business case feasibility.

These three items correspond to the work packages of this programme

Workpackages

The number of carboxydotrophic isolates is still limited, and it is a challenge to isolate novel microorganisms able to convert CO at high rates and possibly produce distinct product profiling. Expanding the range of products from CO may encompass genetic engineering of already isolated or novel carboxydotrophs that can be explored for the production of chloromethane. This project focuses on the discovery and development of thermophilic carboxydotrophs for syngas fermentation. Further, it aims to design and build synthetic anaerobic microbial consortia for the tailored production of a broad range of high-value chemicals from CO/syngas. With the innovative synthetic mixed culture approach, the project targets to produce bespoke fashion products that cannot be produced by a single microorganism.

Leader – Diana Z. Sousa, WUR

The yield in the standard equipment (stirred tanks and bubble columns) for syngas is generally limited by mass transfer limitations and maximum product concentration. To improve the yield, this project aims to design,

- Membrane bioreactor that allows maintaining high concentrations of CO and H2 by either distributed feeding of gas and/or removal of the product

- Spinning disk reactor that allows high mass transfer rates and thus increase the yield of products.

Alongside, the project will combine computational fluid dynamics (CFD) with metabolic models to predict the progress of syngas fermentation in industrial bubble columns. These predictions can be used to formulate design rules for scale-up/down of optimal syngas conversions

Leader – Fausto Galluci, TU/e

In syngas fermentation (using CO, H2, or CO2), high syngas transfer to an aqueous phase remains the challenge. The complete process needs syngas conditioning, downstream separations for liquids and gases, and recycling of unconverted species. This work package links the microbial conversion and bioreactor to overall processes (from crude syngas to recovered product) and further to the economic and environmental impact from cradle to grave.